Gravimetric blenders

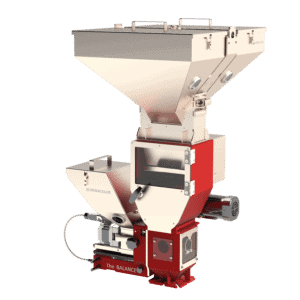

Gravimetric blenders are used in the plastics industry to accurately weigh two or more components and then mix them together before they are processed in an injection molding machine, extruder or blow molding machine. There are two types of gravimetric blenders: loss-in-weight blenders and gain-in-weight blenders. Movacolor’s gravimetric blenders can be equipped with both technologies. This makes it possible to blend and inline dose very accurately in one unique hybrid system.

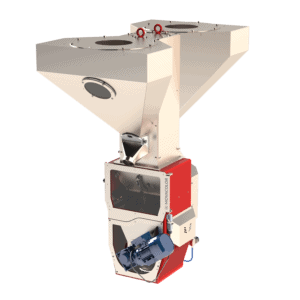

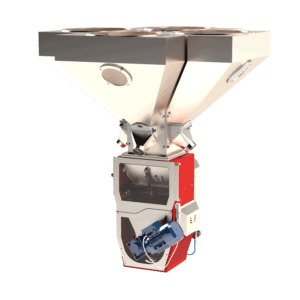

Gravimetric blender based on loss-in-weight technology

A gravimetric blender based on loss-in-weight technology or gravimetric feeder like Movacolor’s MDS Balance measures the weight loss of one or more hoppers using a load cell located under the load frame on which the hopper is attached. The material is dosed with a dosing screw from the hoppers or inline with a dosing cylinder. All materials are dosed together and the dosing rate from each hopper is controlled with a special monitoring system to ensure the correct mix is achieved.

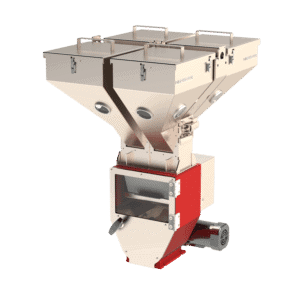

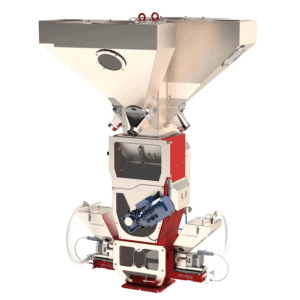

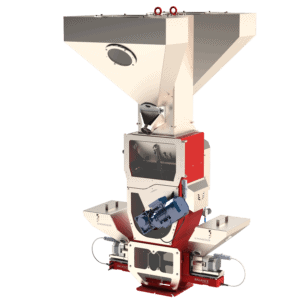

Gravimetric blender based on gain-in-weight technology

A gravimetric blender based on gain-in-weight technology has two or more hoppers positioned above a weighing bin. These hoppers contain the components that need to be mixed. The components are dosed one by one in the weighing bin until the desired weight is reached. Then the entire batch is weighed and mixed in the underlying mixing chamber. When all components have been properly mixed, the mixture is released into the injection molding machine, extruder or blow molding machine. A typical application of a gravimetric blender is to mix materials such as main material, regrind and masterbatch together.