Our solutions can be used in many types of applications

The innovative dosing systems of Movacolor can be used in many types of applications in injection molding and extrusion. Plastic producers of cables, PET preforms, caps and closures and many other injection molding and extrusion applications use our dosing systems to fully control their production process and to save on expensive additives.

Different applications

Applications in extrusion and injection molding all have their specific needs when it comes to the dosing process. Therefor the engineers of Movacolor are constantly working on developing innovative dosing solutions to control any kind of application. Movacolor offers a broad range in gravimetric, optometric and volumetric dosing products to be able to tackle the challenges in the production process of all of these applications.

Applications in extrusion

For all kinds of extrusion applications Movacolor offers innovative dosing solutions. Think of extrusion applications like cables, profiles and pipes. Extrusion applications must meet the highest quality requirements. Movacolor develops high precision gravimetric, optometric and volumetric dosing systems. Our dosing systems are easy to operate and offer full control over your production process, traceability, cost savings and high accuracy.

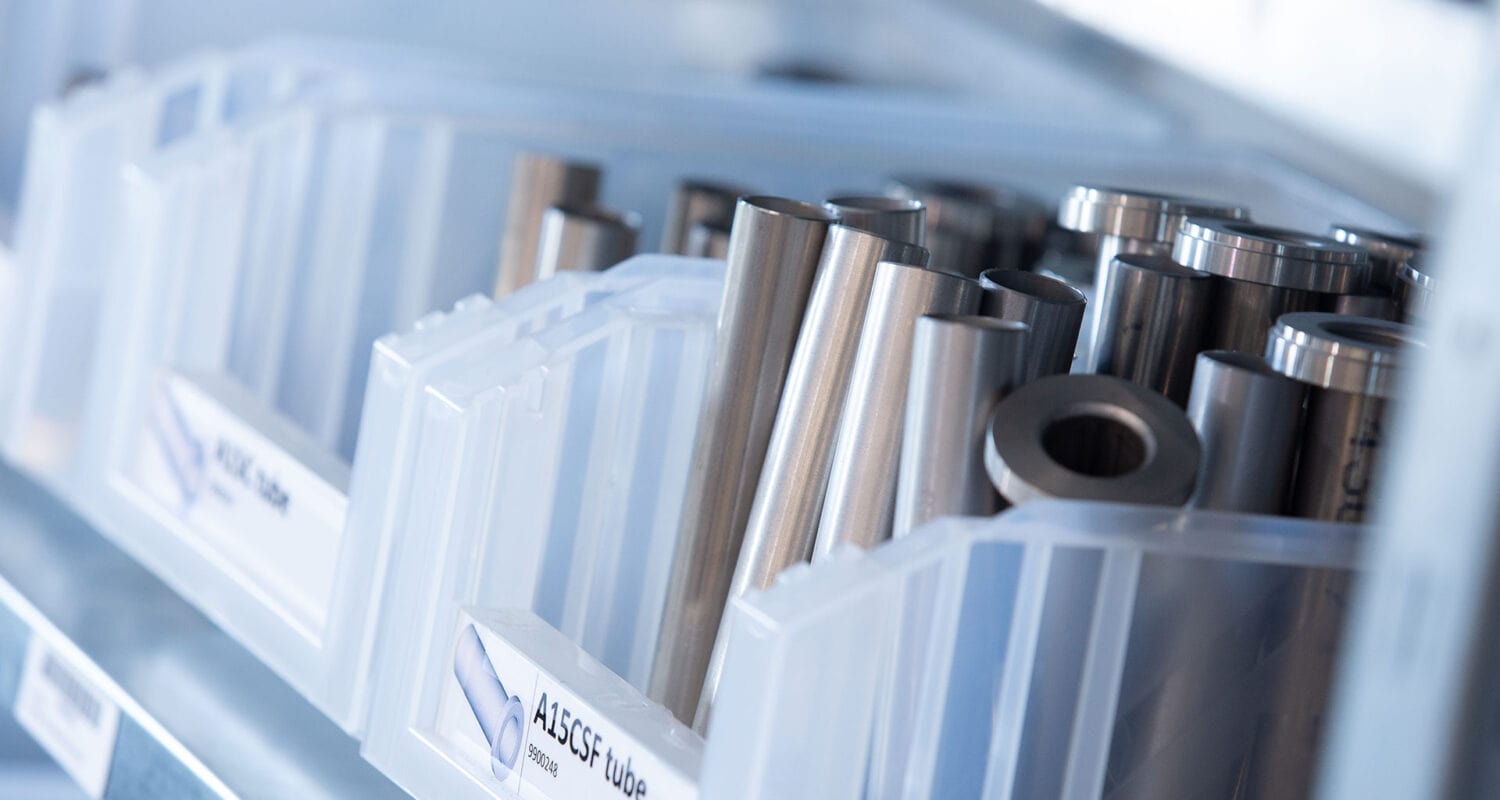

Accuracy is very important during the production of extrusion applications. The high precision dosing of additives like masterbatch, regrind and powder for extrusion applications is based on the use of a dosing cylinder. The Movacolor dosing cylinder is unique in its kind and releases the additive in a steady flow directly into the main material without any pulsations. All our gravimetric and volumetric dosing systems are equipped with a Movacolor dosing cylinder which doses with the highest level of accuracy when its used for extrusion applications.

For the most extrusion applications we advice the MDS Balance, which is the highest standard in gravimetric dosing. Also the MHBS 202 Hybrid Blender is very suitable for extrusion applications. The MHBS 202 Hybrid Blender is unique in its kind and can blend and dose in one system. Thirdly the MMS 40 Weight is highly recommended for extrusion applications. The MMS 40 Weight is a self-regulating material-measuring system for extruders.

Applications in injection molding

A dosing system is a crucial part in injection molding applications. It colors the main material by dosing colorants as masterbatch, regrind and liquids into the main material. For injection molding applications Movacolor offers a wide range of innovative gravimetric, optometric and volumetric dosing systems.

Because of the high output of standardized products in injection molding applications, accuracy is very important. Every product made out of an injection molding application needs the same features as all the other products from the same mold. We can achieve high accuracy in dosing because all our gravimetric and volumetric dosing systems are equipped with a unique Movacolor dosing cylinder. Our dosing cylinder is unique because it releases the additive in a steady flow directly into the main material without pulsations. Dosing with a dosing cylinder is far more accurate than a dosing technique based on blending, using a screw, disc or feeding belt. This especially goes for modern injection molding machines with extreme short production cycles.

For the most injection molding applications we advise the highly accurate gravimetric dosing system MDS Balance. Secondly we advise the MCS Regrind, which is the optimum way to handle regrind in injection molding applications. Also our unique gravimetric blender MHBS 34 Hybrid Blender is particularly suitable for injection molding applications. The MHBS 34 Hybrid Blender is the smaller version of the MHBS 204 Hybrid Blender and also combines dosing and blending in one system.