Pet preforms are typically produced through injection molding, where molten PET plastic is injected into generic preform molds or custom preforms to create the desired shape. After the preforms are formed, they undergo cooling and are then stored or transported to be used in the next step of the manufacturing process.

The advantage of pet preforms is that they can be produced in large quantities and stored efficiently, taking up less space than fully blown bottles. This makes them convenient for transportation and storage until they are ready for further processing.

Once the pet preforms reach the bottling facility, they are heated and placed into a blow molding machine. The machine blows compressed air into the preform, causing it to expand and take the shape of the final bottle or container.

Benefits of PET

- PET is the most recyclable plastic in the world.

- PET is near-infinitely recyclable, which makes it a unique material choice.

- PET is a lightweight material, making it ideal for applications where weight reduction is crucial.

- PET exhibits excellent clarity, allowing for easy visibility of the contents within the packaging, even with color.

- PET is a highly durable material with good resistance to impact and stress. It can withstand rough handling during transportation and storage.

- PET has exceptional barrier properties against moisture, gases, and aromas, helping to preserve quality and freshness.

- PET is a versatile material that can be molded into various shapes and sizes.

- PET is a cost-effective material compared to many other packaging materials.

- PET exhibits excellent resistance to different chemicals, including acids, bases, and solvents, which is especially important in the food and beverage industry.

Colored PET Preforms

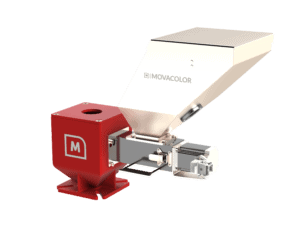

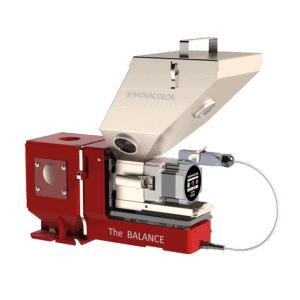

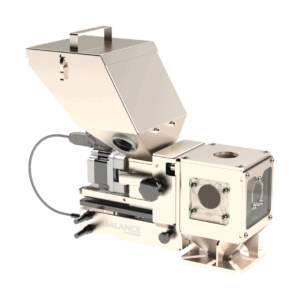

Most used plastic bottles are translucent. However, it is common for beverages (e.g., carbonated) to come in colored preform bottles, including green, red, and orange. Color additives, however, are bad for the environment. Besides, they’re expensive to use in your production. Luckily, we’ve developed a gravimetric dosing unit that ensures flawless color consistency, helping you limit waste and reduce costs significantly.

What are PET preforms used for?

PET preforms can package a wide range of products like mineral water, juices, liquors, soft drinks, carbonated beverages, oils suitable for consumption, medicines, pickles, jams, and other consumer products.

Common Types of PET Preform

Custom PET preform manufacturers specialize in custom PET preform molding. They often work with the company that makes the PET preform designs and deliver the preform solutions directly to the factory.

PCO Preforms:

Make PET bottles for packaging carbonated soft drinks and non-carbonated drinks like juice and milk that don’t have carbonation.

CTC Preforms:

Usually used to package cooking oil and soy sauce.

Alaska Preforms:

They are commonly used to make PET bottles for drinking water.

ROPP Preforms:

Making PET bottles for use in the medicine industry

Other Special Types:

For 5-gallon/20-liter water bottles

What should I consider when purchasing my equipment?

When purchasing equipment for manufacturing PET preforms, you’ll realize that various companies can supply them, and the choice is more complex.

Additives are costly, especially when dealing with color or sunblock additives. Therefore, it is not advisable to look merely at the price when dealing with elements that have substantial costs. Instead, you want to look at what can make the difference between fast, long-term production and a series of unexpected problems that will end in downtime or immeasurable dosing.

To elaborate, most manufacturers dose this without knowing how much material they use. With gravimetric measurement, you can track precisely how much material you’ve used with up to 0.02% accuracy.

What is rPET?

PET that has been recycled (RPET) has previously been used to create another product.

One of the most common polymers we encounter daily is PET or polyethylene. It is extensively utilized in various products, including bottles for food and beverages.

To create rPET, PET is recycled from plastic bottles. Once processed, recycled plastic can create various products, including new bottles, shoes, and athletic apparel.

Choosing rPET promotes the development of a circular economy by keeping valuable resources once harvested from the earth in use.

Processing recycled material

In the plastic manufacturing realm, waste is inevitable. Luckily, by making a wise choice in material, companies can opt to process regrind. PIR, short for Post-Industrial Regrind, is a recycled material made from industrial plastic waste.

How does it work?

It involves grinding the waste into small granules or flakes, which can be used to create new plastic products. As a result, PIR helps reduce the need for new plastic, minimizes waste, and promotes a more sustainable approach to manufacturing. Companies like Movacolor specialize in providing advanced solutions for dosing and mixing PIR with virgin plastic, ensuring precise and efficient processing of recycled materials.

A hypothetical example

Suppose a factory employs a batch blender to make colored PET preforms with a 3% additive percentage. This company is expected to use 377.395 kg of additives per year at a production rate of 1600 kg/h with 24-hour manufacturing. Let’s face it: that’s a lot of money spent on production.

Without processing regrind, 377.395 kg of additives is consumed annually, costing an average of €6 per kg, or €2.267.970 overall.

Have you ever determined how much regrind you can create from your leftover materials to create new products?

10% Regrind – Annual Savings of €267.970*

20% Regrind – Annual Savings of €453.594*

30% Regrind – Annual Savings of €680.391*

This example shows the importance of choosing the material and measuring the output/performance of your dosing for the injection molding machine.

* how much you will be able to save will depend strongly on a variety of factors, like product, process, and material. For personalized advice, contact our product specialists to figure out what’s possible in your production.