At Movacolor, we are committed to integrating hardware and software into our powder dosing units to ensure you can enjoy trouble-free, accurate powder dosing.

Dosing powders in injection molding or extrusion applications is a very specialized business. We successfully incorporated the experiences of powder manufacturers and plastic producers worldwide into the product development process of our powder dosing systems. With Movacolor powder dosing systems, plastic producers can save up to fifty percent on dosing powder additives.

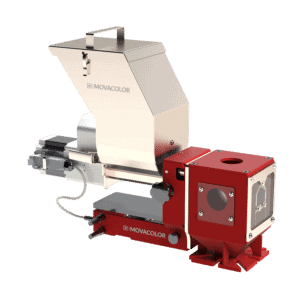

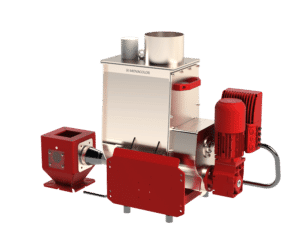

Powder dosing with a gravimetric or volumetric dosing feeder

Free-flowing can be dosed trouble-free with a gravimetric or volumetric Movacolor feeder. The decision of which feeder to choose is whether to go for a small investment and choose a volumetric feeder or save money in the long term and choose a highly accurate gravimetric feeder.

The closed loop and the loss-in-weight technology of a gravimetric feeder offer maximum efficiency and savings when it comes to powder dosing. Movacolor’s gravimetric and volumetric feeders for powder dosing are equipped with a single or double spiral and driven by a stepper motor. This, together with the continuous excitation in the high-grade polished hopper of the powder dosing system, ensures a steady powder flow into the main material stream.

Most of our volumetric feeders require manual calibration. This is in contrast to our gravimetric feeders, all equipped with an automatic calibration function. The volumetric MDS Volumetric Feeder / dosing unit of Movacolor is an exception on the other volumetric feeders and can be pre-calibrated to dose at percentage rates.