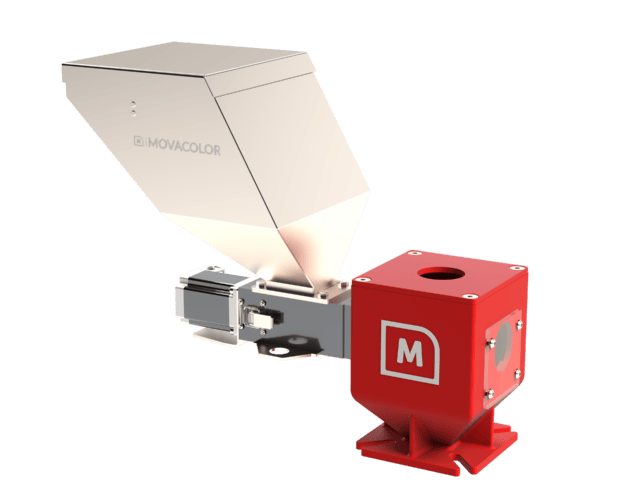

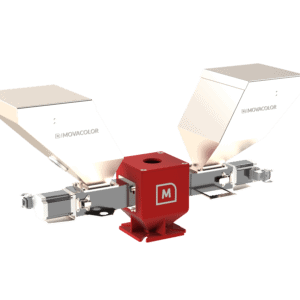

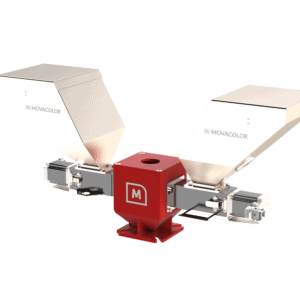

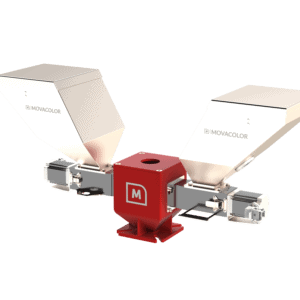

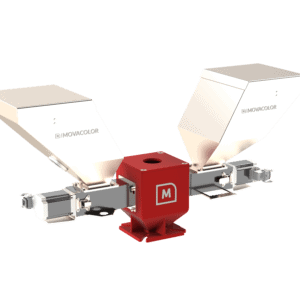

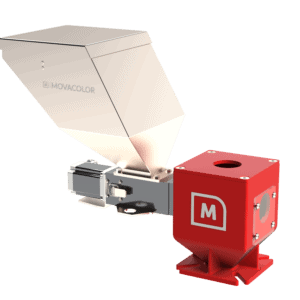

Our brand-new MDS Volumetric Feeder, part of our modular dosing solutions, addresses the need for a well-engineered dosing unit at a cost-efficient price point. This dosing unit offers high value for money, including functionalities from its predecessors, as well as new hardware and software features.

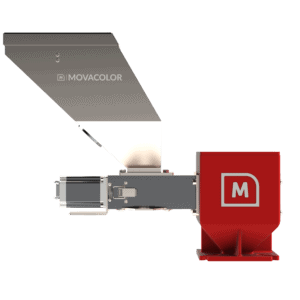

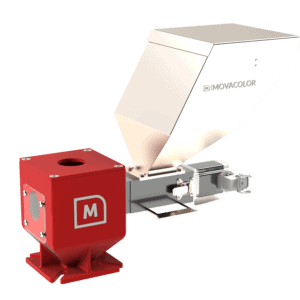

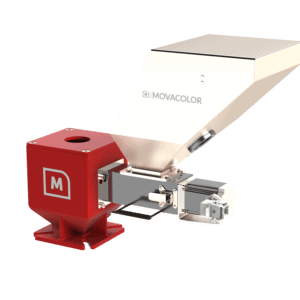

The MDS Volumetric Feeder comes with a high-end stepper motor, a wide selection range of dosing cylinders and augers, a stainless-steel hopper, and a robust neckpiece. Optimal blend homogeneity is accomplished through inline dosing using a centralized neckpiece insert.

The MDS Volumetric Feeder includes a dedicated 4.3” VoluTouch controller. This capacitive touchscreen controller can efficiently manage up to two units and is equipped with intuitive functionalities, offering ease of use through simple recipe management and connectivity via a wireless web interface. Additionally, this dosing solution allows 60-second cleaning and material change through a discharge valve with easy motor and dosing tool release and change.

The MDS Volumetric Feeder allows for trouble-free dosing, with the capability to handle a wide variety of materials, from granular material to microgranulate and free-flowing powder up to 70 degrees Celsius. It proves its value in improving efficiency, reducing waste, and saving costs in injection molding, extrusion, blow molding, and compounding processes.

Standard Equipment:

- Discharge valve

- Power supply

- Stepper motor

- NBST40 neckpiece

- GLX dosing cylinder

- VoluTouch

- 6L stainless-steel hopper

The MDS Volumetric Feeder is part of our modular dosing concept and can be combined with other units and/or specifically tailored to suit the requirements of your production process.

Ready to optimize your dosing precision and efficiency? Contact our product specialists today and discover how our dosing systems can enhance your production processes.