1. Extend Operational Life

The VoluTouch controller is built to last. With an average lifespan of 10 years, it significantly extends the lifetime of your existing equipment. We know that every second of downtime costs money, which is why we’ve engineered our VoluTouch to run continuously, ensuring that your production line remains efficient and reliable over the long term.

2. Reduce CAPEX expenditures

By extending the operational life of your equipment, you reduce the need for frequent capital expenditures (CAPEX). This cost-saving measure allows you to allocate your budget to other critical business areas, enhancing your production line’s overall profitability and efficiency.

3. Seamless Integration and Enhanced Connectivity

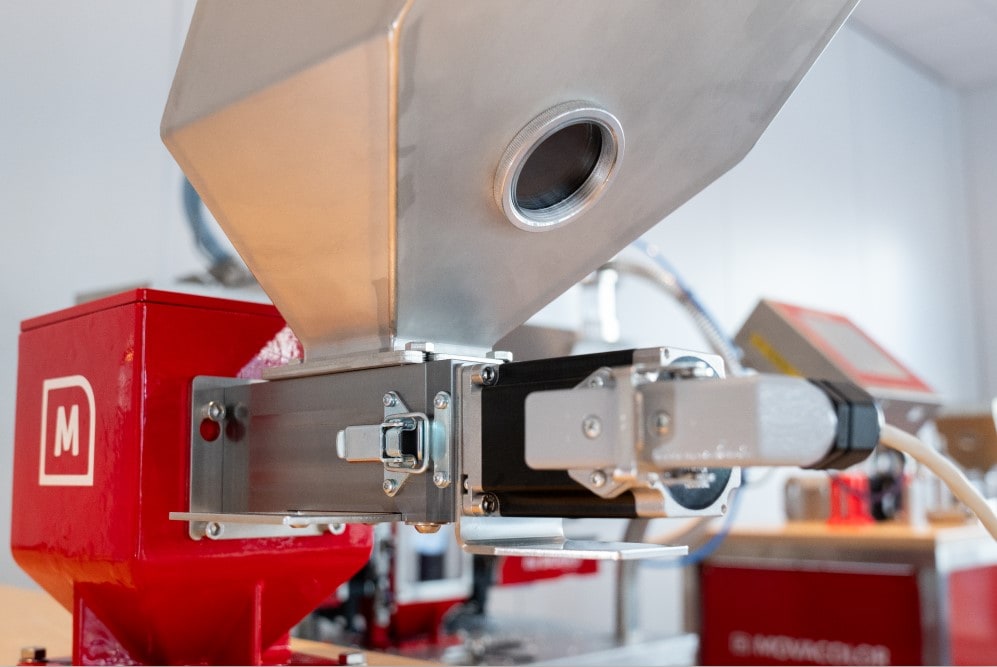

Whether you’re handling granular, liquid, or powder (using the MDS Liquid, Powder, Compact, or High-Output), the VoluTouch controller offers seamless integration with your existing machinery. It connects with an extruder’s tacho signal effortlessly and initiates the injection molding machine in timer mode. Additionally, it features a relay mode suitable for both machine types. This ensures smooth and uninterrupted operations, allowing you to maintain a consistent production flow.