A concern for accuracy

During the field-testing phase, our test customers raised a question regarding the dosing accuracy of the Off-line setup compared to the on-line configuration. This question stemmed from the fact that dosing further away from the material inlet could potentially result in reduced control over the material flow.

To elaborate, manufacturers typically prefer positioning their dosing unit as close to the material inlet (on-line) as possible, to minimize the risk of any interference during the dosing process. Given this setup, the concern expressed by our test customers was understandable, as there is limited control over the material while it is being transported through the hose.

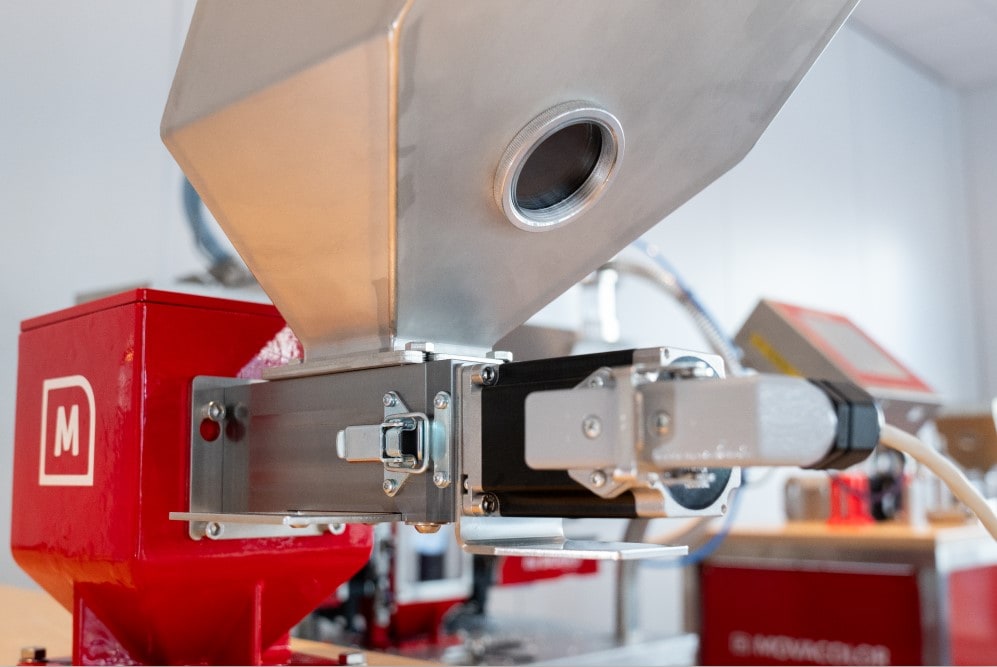

However, our engineers have thoughtfully considered this concer during the development. The Off-line dosing conveys granular materials through a hose to high-placed dosing locations such as vertical injection molding machines. The additives are being conveyed by compressed air directly into the main material stream that is added through a main material hopper on top of the production machine.

When a dosing cycle starts, the material is transported from the stand, trolley or frame to the receiving neckpiece on top of the production machine. An ejector block uses compressed air to transport the material, material is only transported when the unit is dosing. To ensure all the material is transported, an off-delay can be set. The ejector block will be active for this set time after the dosing cycle is finished.

The high-output version of MCS Off-line dosing

Besides our MCS Off-line dosing system, we now developed a high-output version. The MCS Off-line dosing HO is developed for plastics converters requiring transport capacities up to 100 kg/h*.

Maintaining the same innovative design and benefits of our standard MCS Off-line dosing, this high-output version ensures seamless integration into your production process while delivering superior performance. Designed to meet the demands of high-volume operations, it guarantees a high-output without compromising on accuracy, safety or efficiency.

In conclusion

In conclusion, our MCS Off-line dosing brings about a revolutionary change for plastic manufacturers utilizing big extruders, big injection molding machines, and two-component vertical injection molding machines. We have carefully considered and addressed the concerns voiced by our customers, resulting in a solution that prioritizes vibration resistant dosing, safety, accessibility, and convenience within your factory.

Would you like to know more about the features and benefits of our MCS Off-line dosing? Take advantage of a free consultation with one of our application specialists by filling out our contact form below.