Fakuma 2023 promises to become another fantastic show, with nearly 1,500 registered exhibitors and plenty of industry specialists. It’s an event we’re always excited about! Are you?

Because of the size of the exhibition and the timespan of only four and a half days, we understand that you want to make the most of your time and may have to prioritize which booths to visit. In this news post, we’ve summarized everything we’ll be showing at the Fakuma and why you should certainly stop at our booth – Hall A3 Booth 3002.

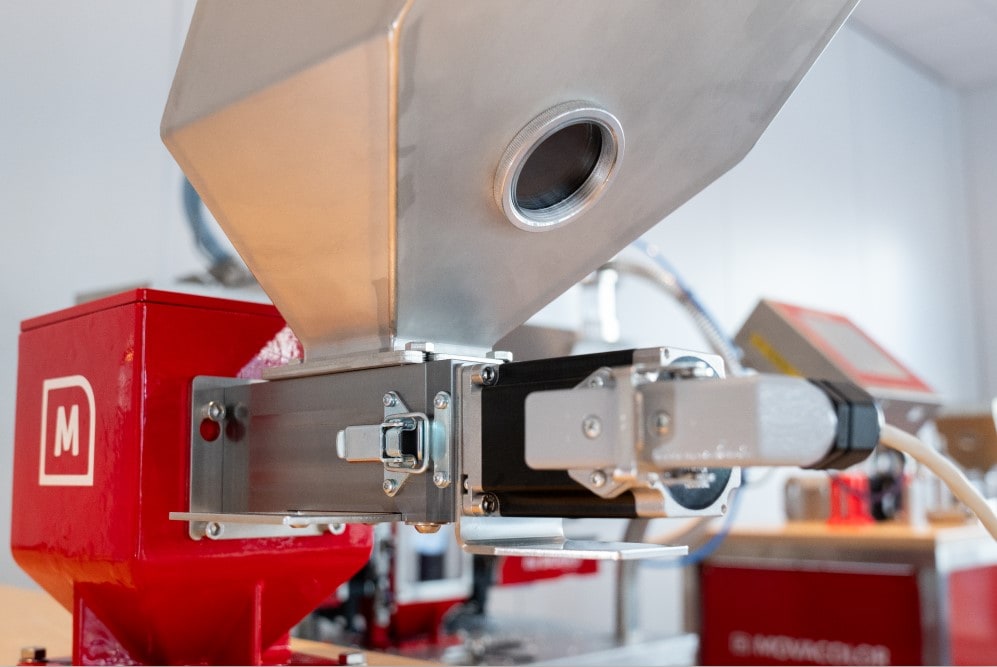

Go beyond blending with our MBS and MHBS blender range

For plastic producers using low-cost materials with a high throughput, batch blenders can be a cost-effective choice compared to dosing units that may be better suited for smaller-scale or continuous processes.

When working with expensive and critical additives in your production process, it is paramount that a batch blender’s dosing accuracy and mixing uniformity is top-notch to avoid overdosing (material cost increase) and underdosing (scrap/rejects rate increase).

Our MBS Blenders can efficiently handle various (low bulk-density) materials and offer extensive control over your production process. They have a compact and sturdy design, with no mechanical or moving parts in the hoppers. They are also part of our modular dosing and blending concept, so they can be tailored to fit your production process.

However, despite the advanced mechanics of our blenders, there are limitations when it comes to accuracy. In comparison to feeders, blenders tend to exhibit higher shot-to-shot fluctuations. Furthermore, inside the blender’s mixing chamber, there is a risk of de-mixing and segregation of dosed materials due to variations in bulk density, resulting in an uneven blend. This issue becomes particularly noticeable when blending low percentages.

As a solution, we encourage plastic manufacturers that opt for blenders to “Go beyond blending.” But what exactly does this mean?

We tackle the challenges mentioned by integrating blending and dosing into a single system known as a hybrid blender. To configure a hybrid blender, you can incorporate up to six gravimetric dosing units, suitable for handling granules, powder, or liquids.

What sets us apart from other suppliers is our use of gravimetric feeders and specialized inserts, which introduce materials’ inline,’ after the batch blender’s mixing chamber, right in the middle of the batch. This innovative approach effectively prevents de-mixing within the batch. It combines the best of two worlds: High throughput gravimetric blending and high accuracy gravimetric dosing resulting in optimal results and traceability.