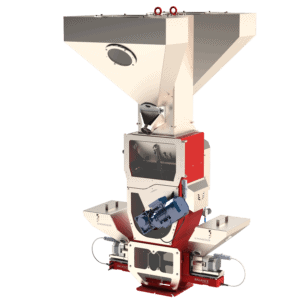

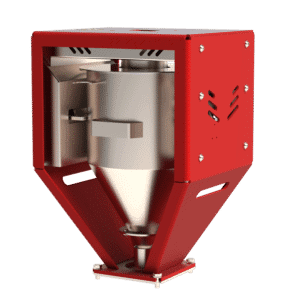

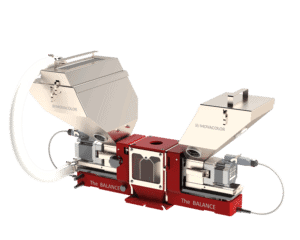

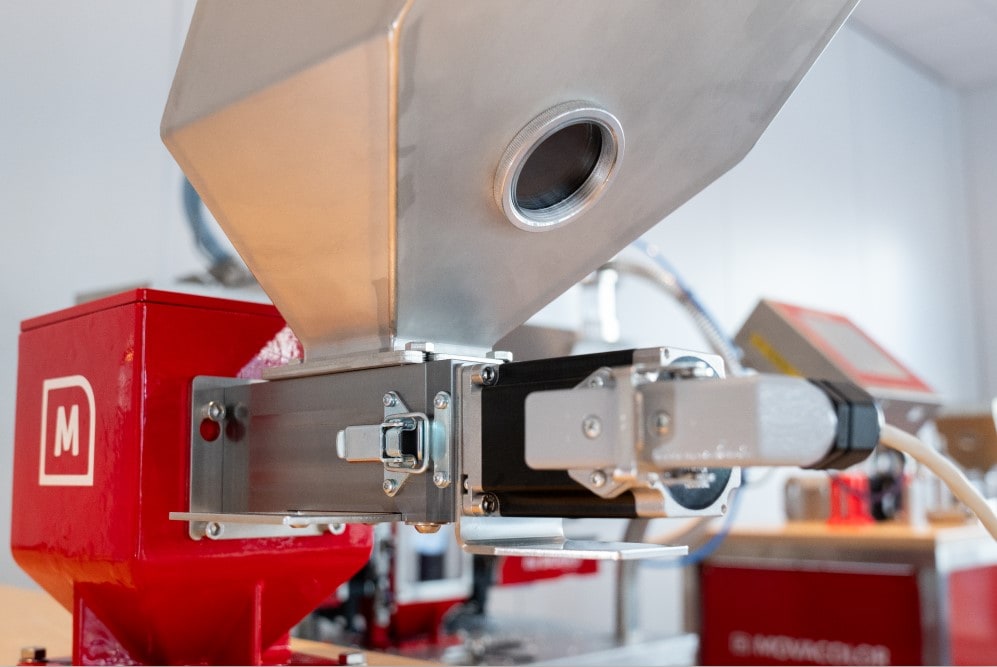

With the MCS Off-line Dosing, operators can now perform essential maintenance tasks at ground level, eliminating the need to work at elevated heights or on top of production machines, resulting in improved safety and efficiency in your production.

Additionally, it allows manufacturers to achieve superior dosing accuracy and blend homogeneity, even in the presence of high vibrations, resulting in consistently high-quality products. Additionally, manufacturers can easily avoid spending €30,000 on buying expensive mezzanine structures.

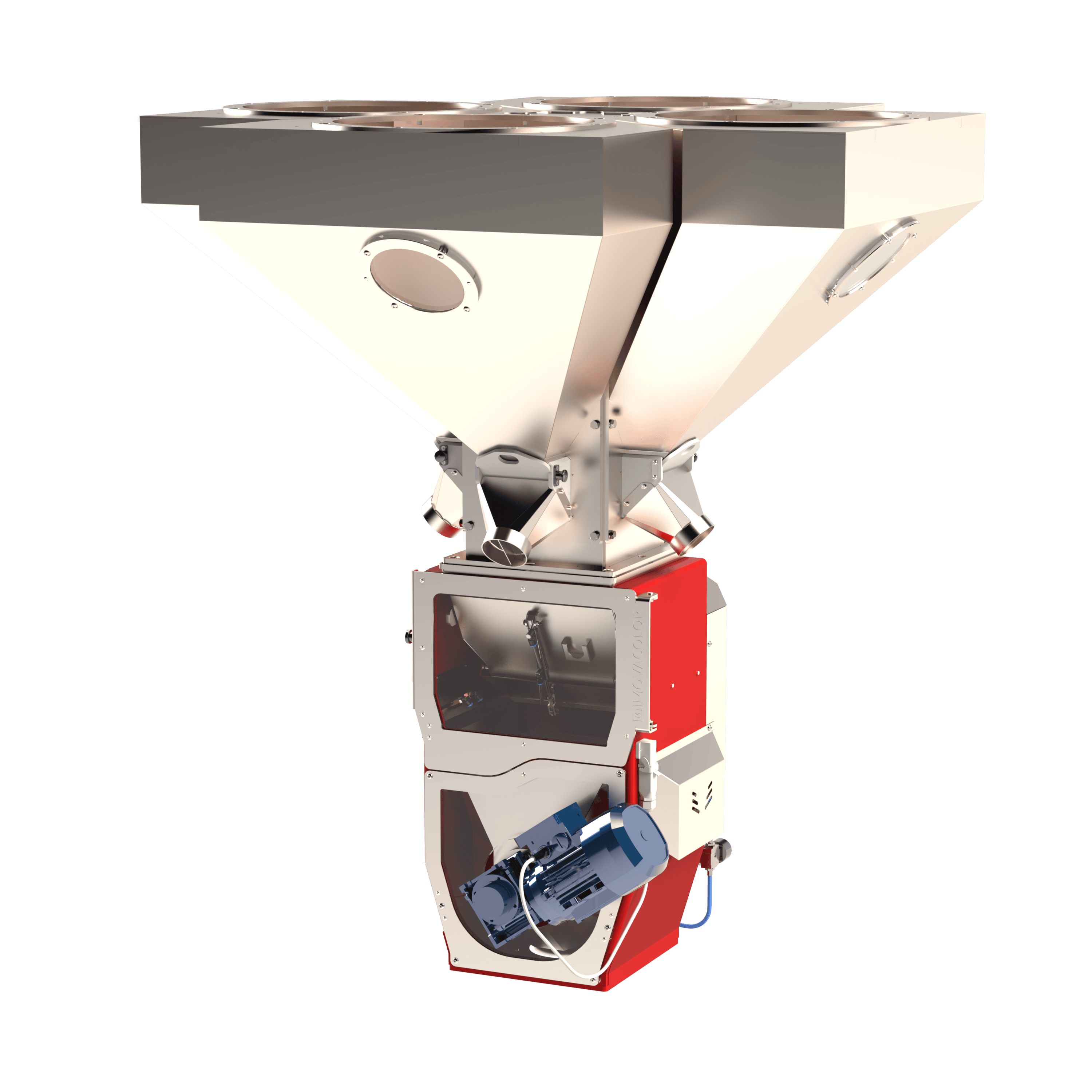

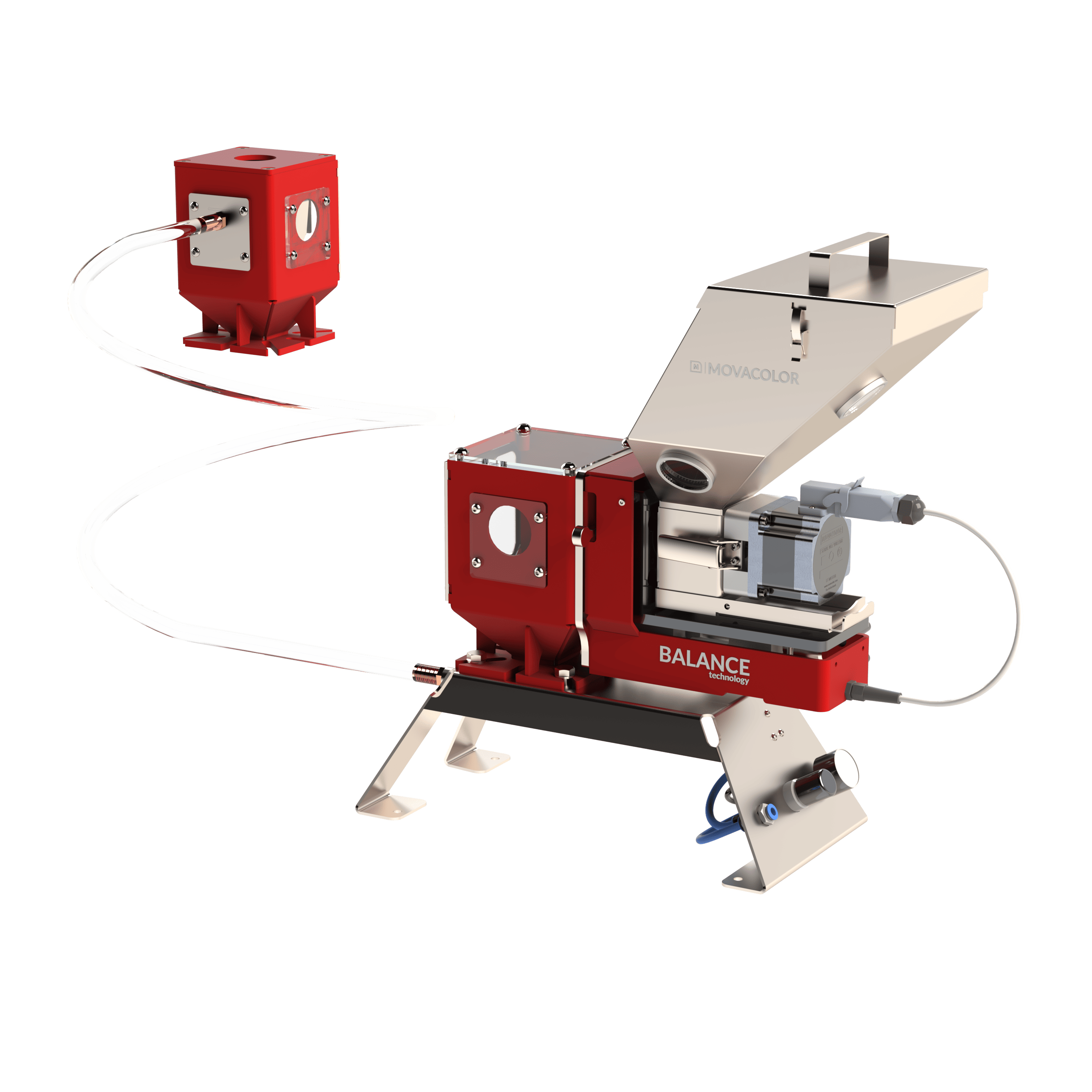

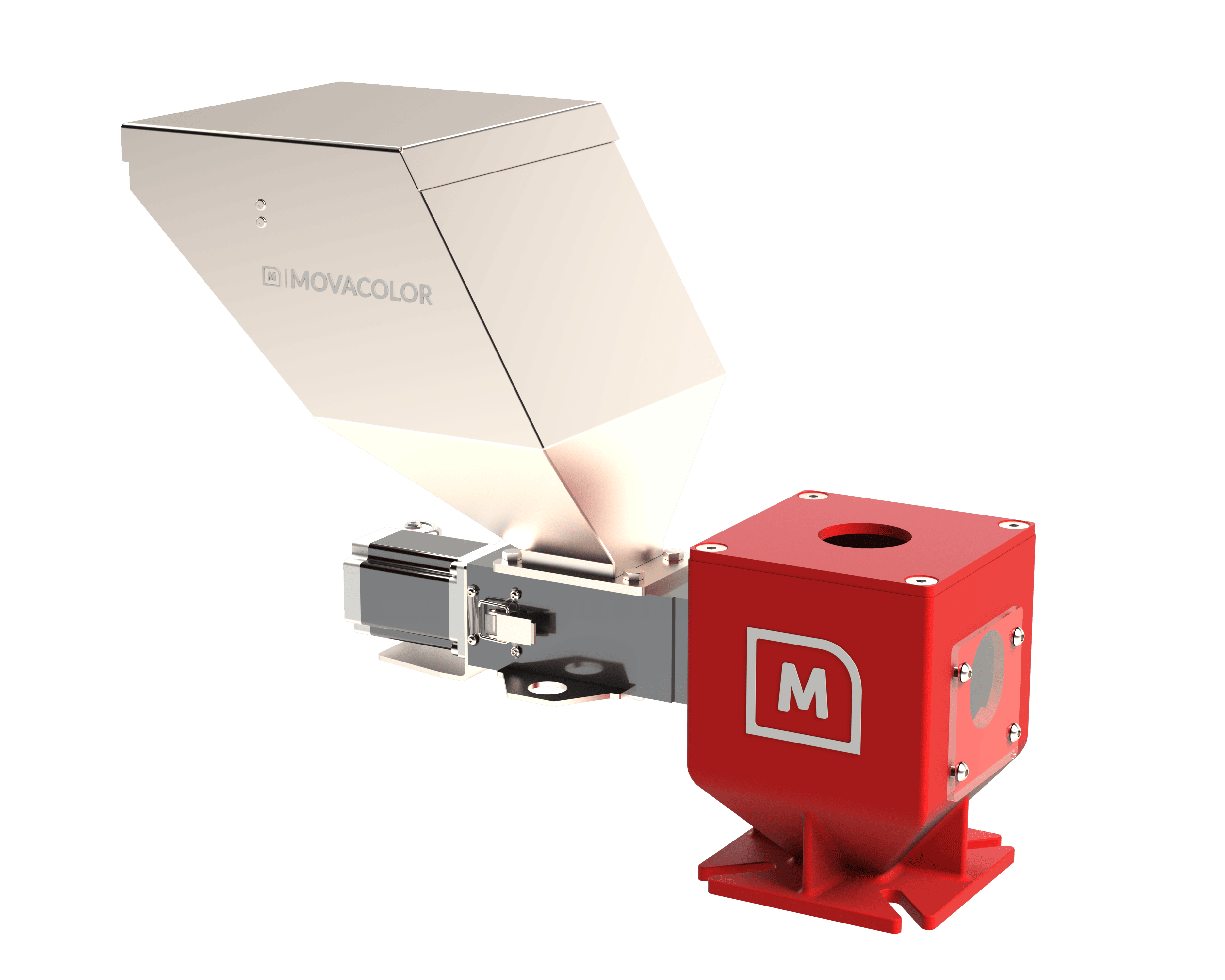

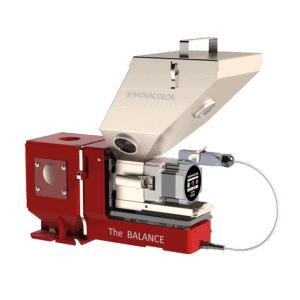

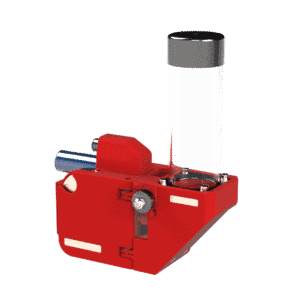

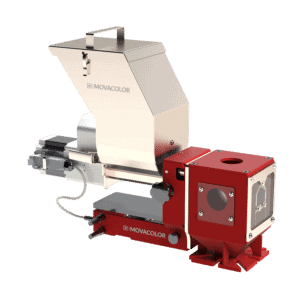

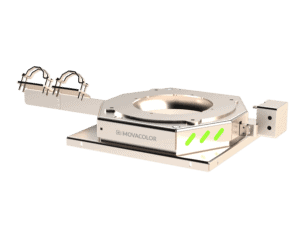

Seeking a customized solution for your factory? Our versatile MCS Off-line Dosing is available in three different configurations, which consist of a movable frame, stand, and trolley configuration. Visit our stand at NPE to explore which off-line dosing configuration is best for improving your production process!