Introduced in 1997, our first generation volumetric units have demonstrated their worth across diverse applications. Throughout the subsequent decades, our engineers have consistently refined and advanced their development to align with the evolving demands of the industry. Now, we are delighted to launch the MDS Volumetric Feeder, setting the new standard for plastic volumetric dosing solutions.

This new volumetric dosing solution – backed by the tagline ‘Volumetric Dosing Done Right’ – is specifically developed for manufacturers in search of a cost-effective solution to significantly enhance material handling- and operator efficiency in their production processes.

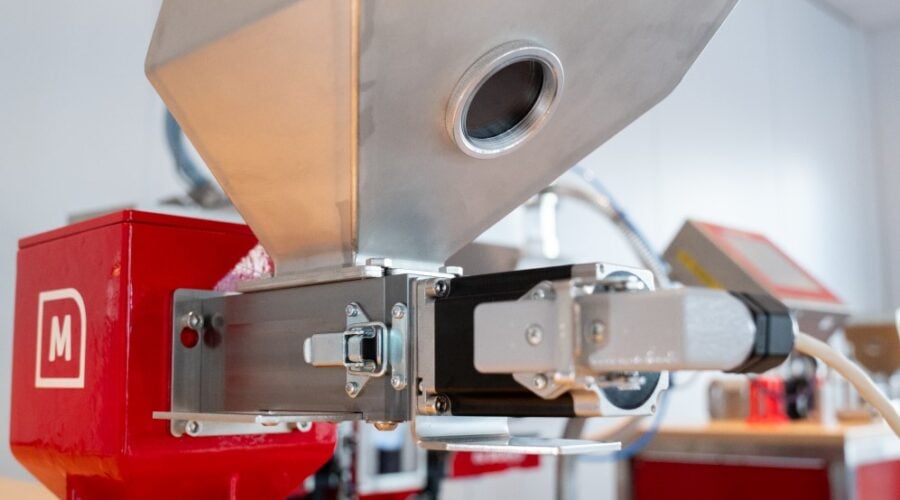

The MDS Volumetric Feeder is equipped with a robust stepper motor, a stainless-steel hopper and a sturdy neckpiece. Achieving optimal blend homogeneity is ensured through inline dosing, facilitated by a centralized insert within the neckpiece.