Gravimetric and Volumetric Feeders for Blow Molding

Movacolor is dedicated to providing precise dosing solutions tailored for blow molding applications. Our expertise lies in developing and supplying reliable gravimetric and volumetric feeders, contributing to the elevated quality of plastic parts production in blow molding. Our engineers continuously refine dosing techniques to ensure optimal performance.

Our masterbatch, powders, and regrinds dosing approach centers around our distinctive dosing cylinder. Incorporating this cylinder guarantees highly accurate dosing, whether it’s a gravimetric or volumetric feeder. The dosing cylinder releases additives seamlessly into the main material, ensuring a steady flow without pulsations or interruptions, setting a new standard for precision in blow molding.

Including a stepper motor in our feeders ensures precise control without stoppages or pulses. This dosing method, centered on the dosing cylinder, outperforms alternative techniques like blending, screw-based, disc-based, or feeding belt-based dosing. This advantage is particularly valuable in modern blow molding machines that demand short production cycles.

Blow Molding Applications with Gravimetric Dosing Technology

Our gravimetric feeders, recognized as loss-in-weight feeders, are known for their exceptional accuracy, thanks to our unique gravimetric dosing technology. Our gravimetric feeders shine in blow molding processes, where consistency is paramount. Equipped with a load cell, these feeders precisely measure the weight of additives added to the main material stream, ensuring a consistently high-quality output from the blow molding machine.

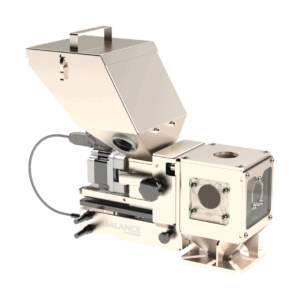

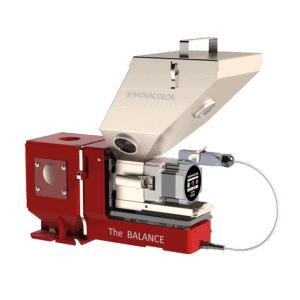

A Modular Dosing System for Blow Molding

Our gravimetric and volumetric feeders, thoughtfully designed for the blow molding industry, prioritize user-friendliness and versatility. The modular design empowers operators in the plastics industry to craft a tailored dosing unit that aligns seamlessly with their specific production requirements. The dosing unit’s adjustability, extendability, and upgradability provide flexibility for diverse production processes.