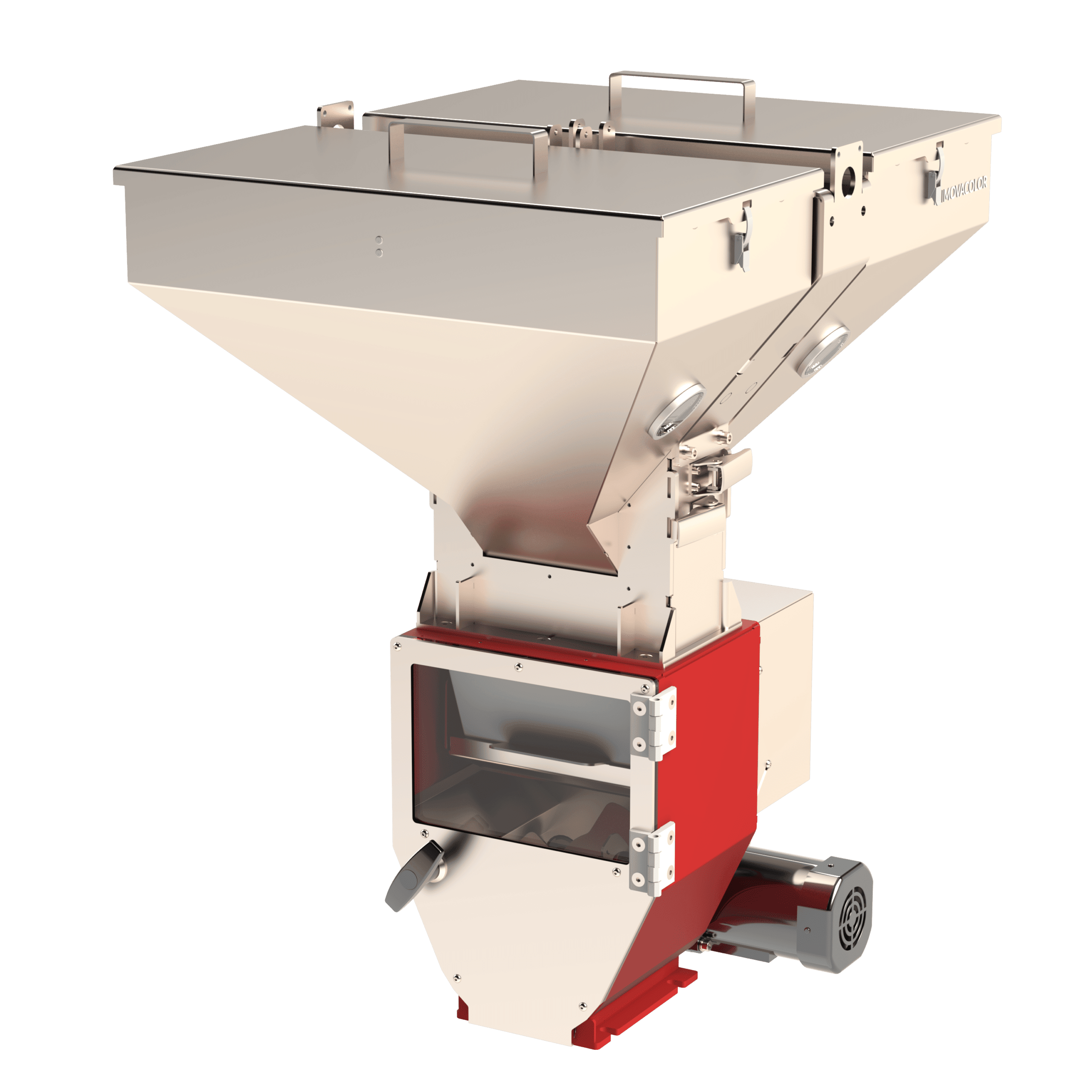

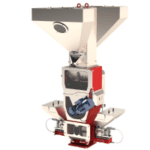

The MBS Blender 3-series, part of the MBS blender range, provides a robust and durable solution for efficiently weighing and blending materials. Its compact design without mechanical parts or cables in the removable hopper allows them to be easily accessible for cleaning, material changes, and other routine maintenance tasks. Additionally, the blender 3-series is perfectly suitable for handling a wide range of materials up to 70 degrees with a throughput of up to 480kg/h.

Thanks to its unique valve design and gain-in-weight technology, it effectively dispenses several additives into a weighing chamber and accurately measures the additives added to your production process. After your material is weighed, it’s dropped into the mixing chamber, and fed to your production machine.

The MBS Blender offers all manufacturers extensive control over their production process and consistently proves its value in all applications by helping manufacturers significantly improve efficiency, reduce waste, and save costs, resulting in savings on materials and improved quality.

The MBS Blender 3-series can be upgraded to a MHBS Hybrid blending system for optimal control over critical or expensive additives. This hybrid system combines gravimetric blending and dosing in one integrated system.

Standard Equipment

- Weighing bin with 1.4kg batch size

- 3-liter mixing chamber

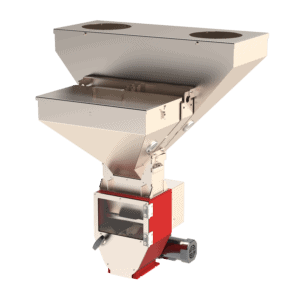

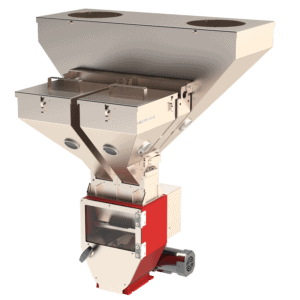

- Easy hopper removal system

- Easy weighing bin, mixing chamber and mixerblade removal system

- Mixing chamber level-sensor air-purge

- Compressed air-gun system

- 8“ full color portable touchscreen controller

- Unique mixerblade

- Hopper loader lifting device

Features

- Compact and robust stainless-steel batch blender

- Consisting of a 3-liter mixing chamber with 1,4 kg batch size

- Configurable with 2, 3 or 4 stainless-steel material hoppers

- Range of valves for handling a wide variety of materials

- High accuracy through unique vertical valve design and protected loadcells

- Best-in-class mixing performance and blend homogeneity through unique mixerblade

- Removable hoppers, mixerblade, mixing and weighing bin for quick cleaning and material change

- Integrated cabling and no mechanical and/or moving parts inside the hoppers allowing smart maintenance

- Unique hopper-loader lifting device for easy removal of material hoppers

- Vibration management through unique algorithm

- Regrind control allowing maximization of regrind consumption

- Intuitive 8” full color portable touchscreen controller packed with features and functionalities

- Standard able to handle material up to 70°C, special version up to 120°C

- Max full gravimetric mode throughput: 480 kg/h* – semi-gravimetric mode provides approx. 50% extra capacity