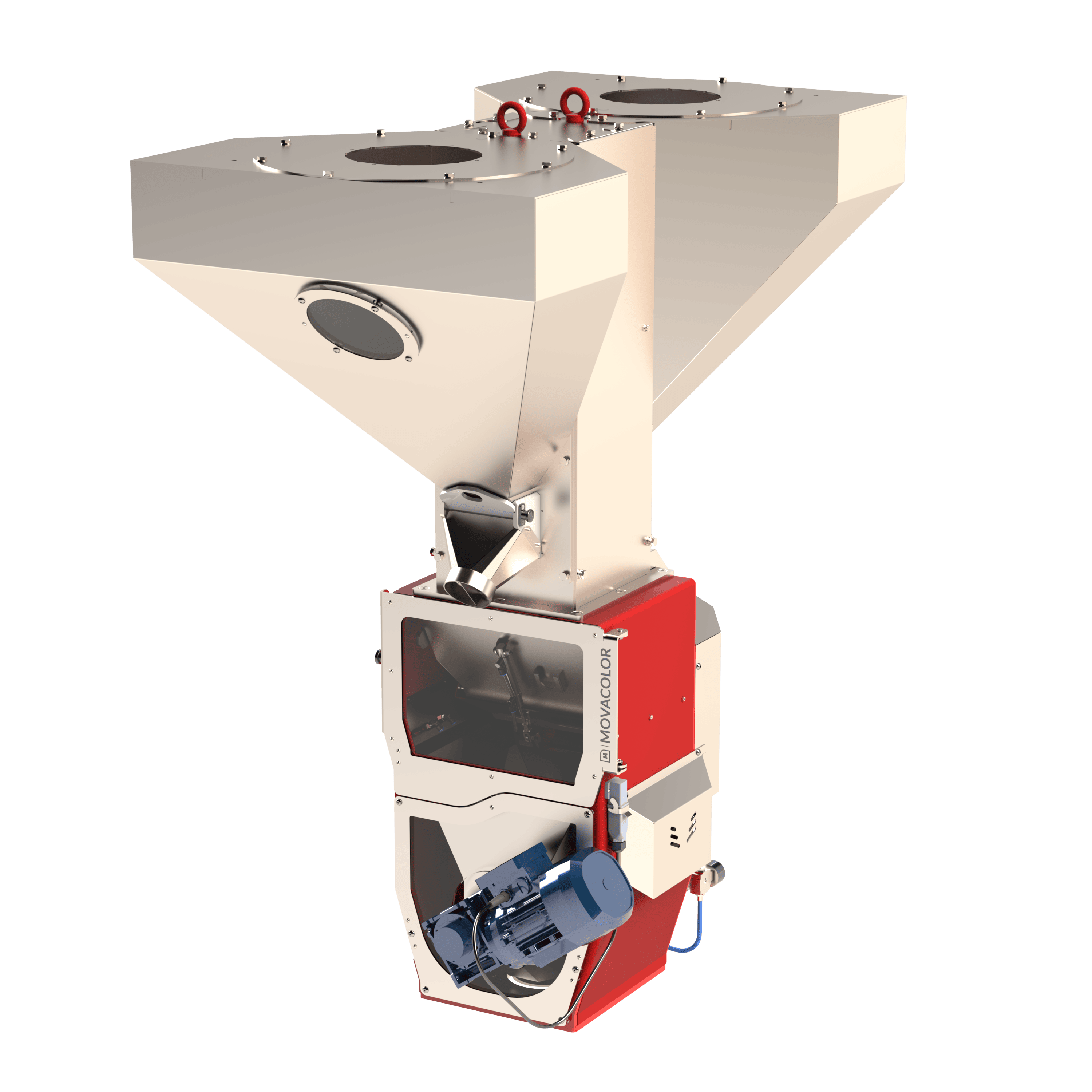

The 20-extrusion series blender has all the functionalities of the regular 20-series blender, but includes a weighing mixing chamber resulting in an integrated continuous loss-in-weight extrusion control. This allows the plastic processer to measure the real-time throughput (feed capacity) of their extruder and track the consumption of materials. Also, it provides quick response to capacity variation of the extruder. When opting for a MHBS 20-extrusion series, it also automatically adjusts additive dosing from the MDS Balance units according to the extruder capacity variation. This solution provides the operator and line manager tools to get the best out of their extrusion line and brings major benefits to extrusion applications such as pipe, profile, cable, wire, and sheet.

The MBS Blender 20-extrusion series can be upgraded to a MHBS Hybrid blending system for optimal control over critical or expensive additives. This hybrid system combines gravimetric blending and dosing in one integrated system.

Standard equipment

- Weighing bin with 7.5kg batch size

- 20-liter mixing chamber

- Hopper drains

- Easy weighing bin removal system

- Mixing chamber level-sensor air-purge

- Compressed air-gun system

- 8“ full color portable touchscreen controller

- Unique mixerblade

- Activated weighing mixing chamber resulting in an integrated Loss-in-Weight extrusion control

Features

- All functionalities of the 20-series

- Activated weighing mixing chamber resulting in an integrated Loss-in-Weight extrusion control

- Real-time extruder throughput (feed capacity) measurement – tracks consumption of your materials

- Quick response to capacity variation of the extruder – adjusts additive dosing accordingly

- Perfect for extruders who want to get the best out of their extrusion line