Our renowned MDS Balance helps manufacturers accurately dose additives with 0.5% accuracy. However, it is important for some clients to get additional control by adding an MMS Weight to measure the main material flow in both throughput and kg/h. This new configuration provides additional control and insight and allows:

- Operators to dynamically adjust dosing rates according to main material consumption.

- Measurability for a wide variety of additives, including regrind, powder, and masterbatch.

- Several departments to measure total main material consumption.

- Automation of the order process for main materials as well as additives.

- Full traceability of all materials in production.

When you add the MMS Weight to the process you simply get even more control and insight.

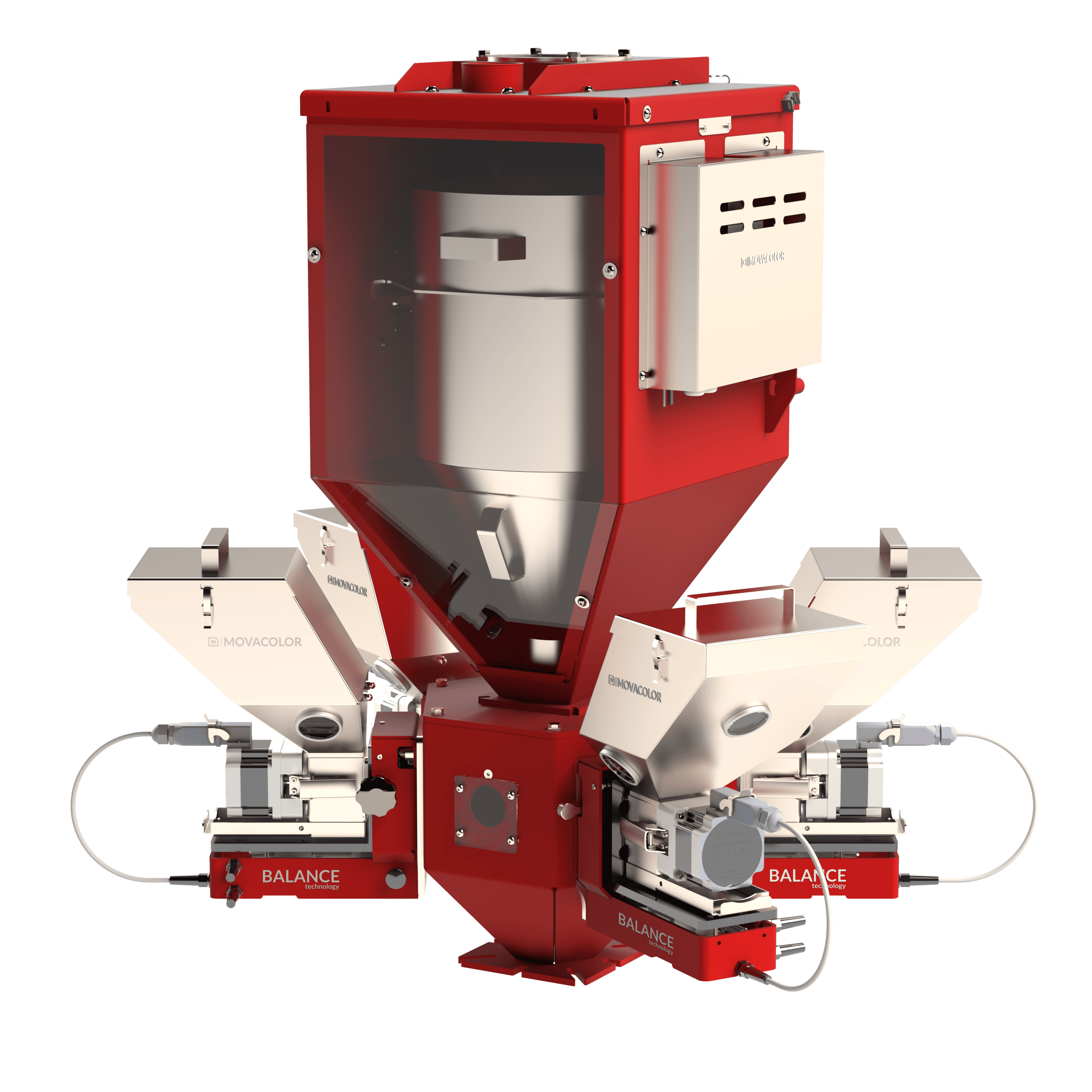

Introducing the MCS Continuous Feeder, part of our configured solutions, equipped with MDS Balance(s) for precisely measuring and dispensing additives with 0.05% accuracy, as well as our MMS Weight for measuring the main material consumption in your production line.

By combining the MMS Weight with our MDS Balance, the MCS Continuous Feeder can measure both main material and additives, resulting in the most cost-effective dosing accuracy possible in your production. The technology behind measuring your main material ensures that your gravimetric dosing units automatically adjust the feed rate to bulk density changes, material consumption, and capacity variation of the extruder.

With the MCS Continuous Feeder, extrusion manufacturers can now measure main materials accurately, helping them dose both main material and additives accurately, resulting in increased consistency, lower additive usage, and real-time data monitoring of material consumption.

Contact our product specialists today and discover how the MCS Continuous Feeder can optimize your production in the extrusion processing industry.

Are you seeking a customized solution for your factory? Our versatile MCS Continuous Feeder is compatible with different applications and can be tailored to your production needs. Whether you’re handling powder, masterbatch, or regrind. reach out to one of our product specialists to explore the possibilities for improving your production processes.