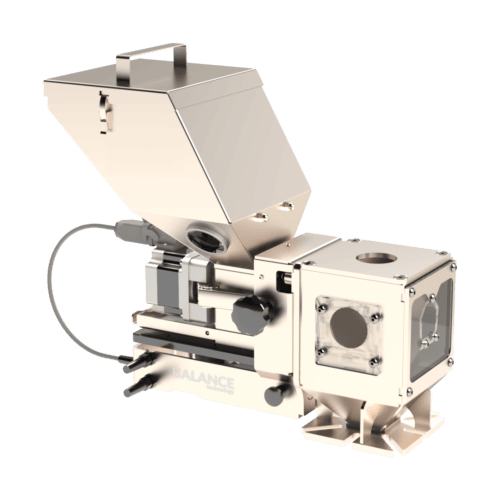

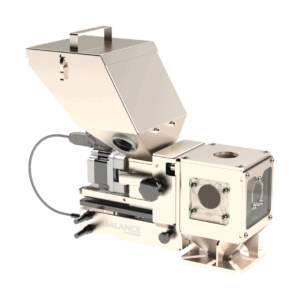

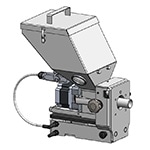

The MDS Balance is a renowned gravimetric dosing unit known for its highly accurate inline dosing capabilities and innovative features. The cleanroom version is equipped with food-quality seals specified for use in most medical and cleanroom applications. It has a completely oil-free design, and all powder-coated materials are replaced by stainless steel. The controller has no external ventilation, and the entire unit can be cleaned with isopropyl alcohol.

- 8” full-color touchscreen controller without external ventilation

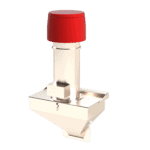

- Stainless-steel hand-slide hopper drain system for a 60 second clean out

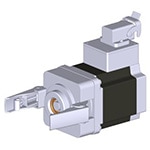

- Easily removable and oil-free low torque motor with food-quality seals

- GLX dosing cylinder with food-quality seals

- Stainless-steel NST40 neckpiece with single-insert

- Stainless-steel load frame

The MDS Balance Cleanroom is part of our modular dosing concept and can be combined with other units and/or specifically tailored to suit the requirements of your production process.

Ready to upgrade your dosing precision and efficiency? Contact our dosing specialists today and discover how the MDS Balance Cleanroom can optimize your production process.