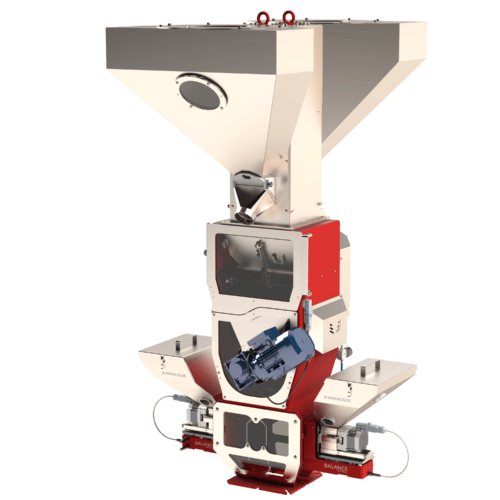

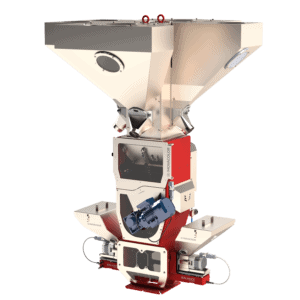

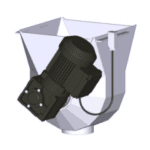

The MHBS 20-series is a hybrid solution developed to help manufacturers who want to improve their shot-to-shot blending accuracy while maintaining high throughput blending of main materials. It stands out on the market due to its innovative combination of gravimetric blending and gravimetric inline feeding, setting new standards for precision and accuracy in the blending industry.

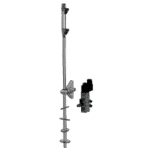

Configurable with up to six MDS Balances and specialized inserts, the MHBS Hybrid Blender is able to precisely dispense your most valuable additives with temperatures up to 70 degrees and a throughput up to 1600 kg/h. The MHBS blender achieves the highest possible accuracy by inline feeding critical additives directly into the pre-mixed material batch. The gravimetric dosing units equipped with our unique Balance technology deliver a remarkable 3x improvement in shot-to-shot accuracy compared to our MBS Blender.

The MHBS Hybrid Blender offers plastic processors complete control over their production processes and consistently proves its value in various applications, including plastic packaging, construction, automotive and medical device production.

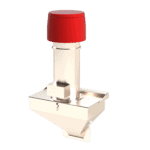

Due to its key feature of inline feeding, the MHBS Hybrid Blender can significantly enhance batch uniformity, minimize de-mixing risk, and provide added traceability for critical additives. This translates to substantial material cost savings and reduced product rejects.

Standard equipment

- Weighing bin with 7.5kg batch size

- 20-liter mixing chamber

- Hopper drains

- Easy weighing bin removal system

- Mixing chamber level-sensor air-purge

- Compressed air-gun system

- 8“ full color portable touchscreen controller

- Unique mixerblade