The MMS Totalizer is engineered to precisely measure main material consumption, enhancing control over your production processes. Specifically designed to measure the consumption of granular main material, it seamlessly integrates into existing Movacolor setups and non-Movacolor setups.

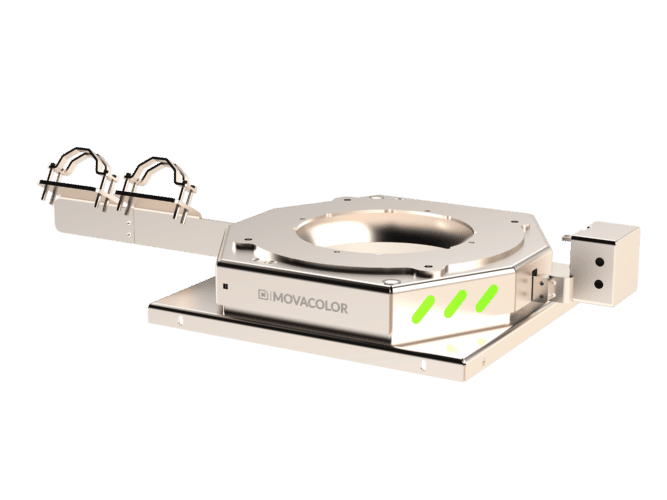

The MMS Totalizer is equipped with a measurement system for load cycles (sensing device) between a loader/receiver and a material vessel (hopper, bin, or other material storage containers.) The two high-precision load cells integrated into the unit measure the weight of the material, which provides real-time insight into the consumption of your main material and the ability to track consumption tied to a production lot number.

The MMS Totalizer can be fitted with various hopper loaders, providing adaptability to different production requirements. The top plate of this unit features an adapter plate that can be mounted to accommodate loaders with an outlet diameter of up to 280 mm. The system can connect to a wide range of material tubes with different tube holders.

Indication lights positioned on all four sides of the MMS Totalizer allow for easy status checks of the full-color touchscreen controller from any angle, providing a 360-degree view of the machine’s operation. Additionally, the modularity of this unit ensures effortless integration into existing setups, making it suitable for a wide range of factories across the globe.

Standard Equipment:

- 8” full-color touchscreen controller

- Two integrated load cells

The MMS Totalizer is a valuable addition to the Movacolor system, offering precise main material consumption measurements for optimized production processes.

Ready to enhance your control over main material consumption? Contact our product specialists today and discover how the MMS Totalizer can integrate seamlessly into your Movacolor setup.