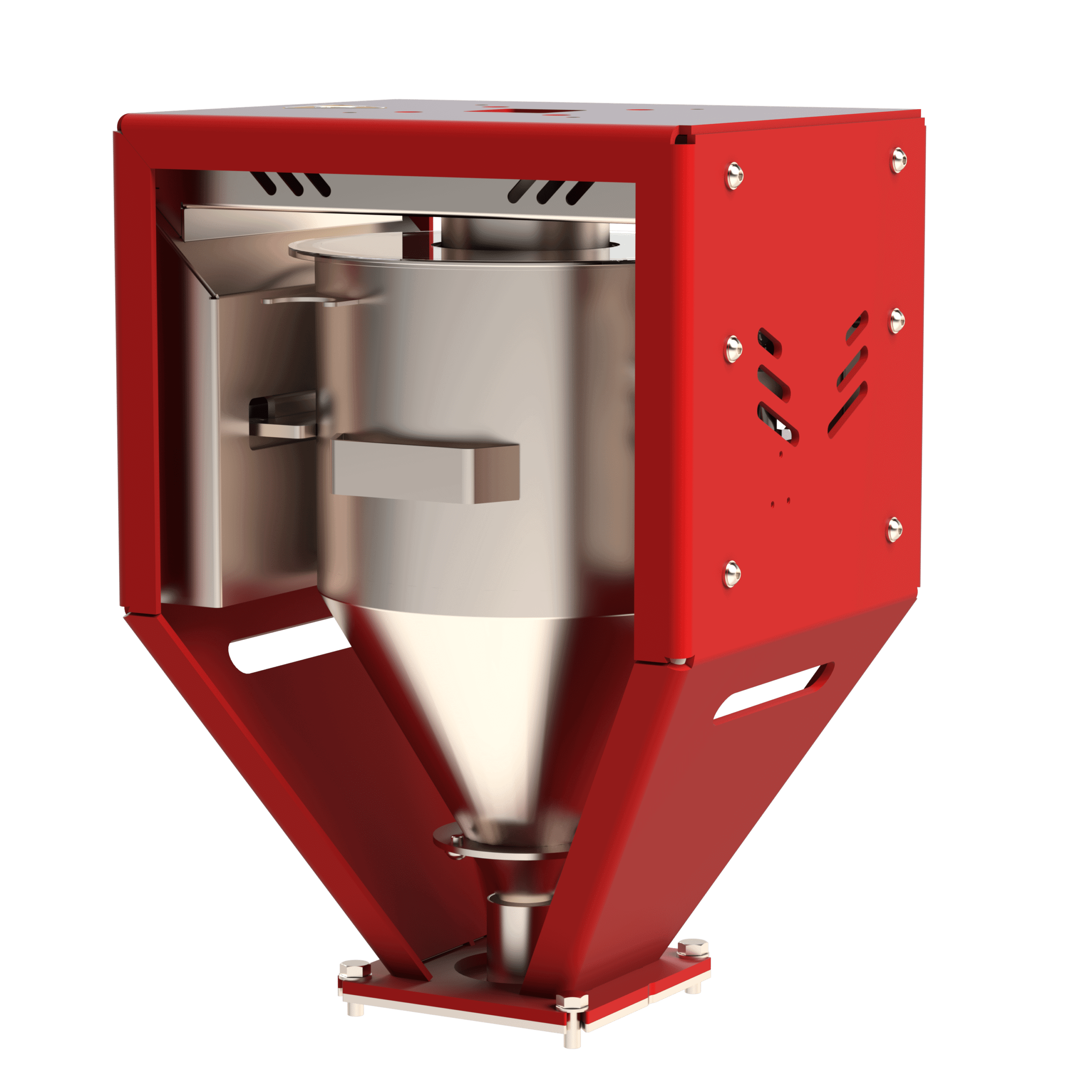

The MMS Weight, part of our measuring solutions, was introduced to the market to provide accurate and real-time measurement of extrusion line capacity and main material consumption.

Equipped with advanced kg/h and integrated load cells with loss in weight features, the MMS Weight is able to provide real-time insight into extrusion line capacity and main material consumption in kg/h.

With the MMS weight, the technology behind measuring your main material ensures that optional gravimetric dosing units (MCS Continuous Feeder) automatically adjust the feed rate to bulk density changes and the capacity variation of the extruder.

The MMS Weight is suitable for precise measurement of extrusion line capacity and material consumption measurement. Due to its modular, scalable design and removable stainless-steel hopper, the MMS Weight allows you to save money and time by easily cleaning your hoppers and changing materials without experiencing significant downtime.

The MMS Weight is designed for extrusion manufacturers who prioritize control and efficiency. The system’s modular design and stainless-steel hopper enable seamless operation with pourable powders, such as PVC dry blend, masterbatch, and regrinds up to 180 degrees Celsius. Additionally, it allows you to control multiple co-extruders through a single interface for maximum ease of use and operator control.

Standard Equipment

- 40-liter stainless-steel hopper – capacity up to 1000 kg/h

- Two integrated loadcells 20kg

- 8″ inch full-color touchscreen

- Pneumatic knife gate

- Calibration weight

The MMS Weight is part of our modular dosing concept and can be tailored to suit your production process.

Ready to enhance your dosing precision and efficiency? Contact our product specialists today and discover how the MMS Weight can optimize your production processes.