Volumetric dosing is a popular technique used across various industries to dispense materials based on volume and revolutions per minute. Unlike gravimetric dosing, which relies on weight measurement, a volumetric feeder dispenses a volume of material based on revolutions per minute. While it may not offer the same level of precision as gravimetric methods, a volumetric feeder remains a practical choice in scenarios where accuracy might not be as crucial.

The volumetric dosing process typically involves the following:

- Calibration – Calibration in volumetric dosing refers to determining the volume of material to be dosed, based on the rotation speed of the dosing tool in combination with the dosing time. By calibrating effectively, manufacturers can, to some extent, achieve constant and reliable performance, decreasing the risk of over- or under-dosing.

- Dosing – Based on the pre-established rotations per minute and dosing time, the material is dispensed into the production process.

Volumetric dosing offers several advantages:

- Simplicity – Volumetric dosing systems are generally not very complex, making them easy to implement and maintain.

- Cost Efficiency – Volumetric dosing setups are often more cost-effective for initial costs, which can be advantageous for producers prioritizing economic considerations above accuracy.

- Material Compatibility – Volumetric dosing is suitable for a wide range of materials, such as liquids, powders and granules.

Volumetric dosing, in comparison to gravimetric methods, demonstrates certain limitations in accuracy. This is because the feed rate and time of the dosing tool are not automatically adjusted when there are changes in material density, viscosity, or environmental conditions. These can introduce inaccuracies in volume-based dosing, whereas our gravimetric balance technology automatically rules out these factors via advanced software.

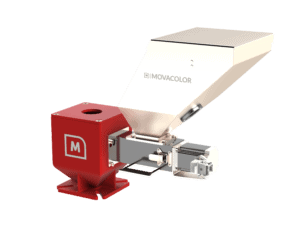

Enhance Efficiency with a Volumetric Feeder from Movacolor

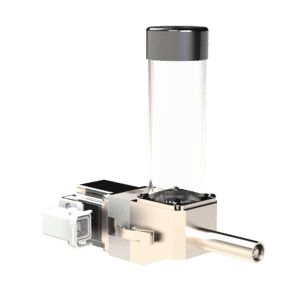

Our range of inline volumetric feeders cater to diverse injection molding and extrusion applications. Opting for our inline volumetric dosing solutions can streamline your processes, potentially reduce costs, and enhance production efficiency, especially when you are still mixing your materials by hand. All our volumetric dosing systems can be equipped with our unique high-accuracy dosing cylinder. This dosing cylinder doses the additive in a steady flow directly into the main material flow without any pulsations or interruptions, ensuring far more accurate dosing than other volumetric dosing techniques using a traditional auger.

Our innovative modular dosing concept enables you to tailor your setup and even combine various units, guaranteeing a dosing system perfectly aligned with your production needs. If you’re facing challenges in identifying the optimal solution for your production process, please share your contact information in the provided form below.

Are you curious about all the details of our MDS Volumetric Feeder? Our team of dosing specialists will be happy to reach out to you!