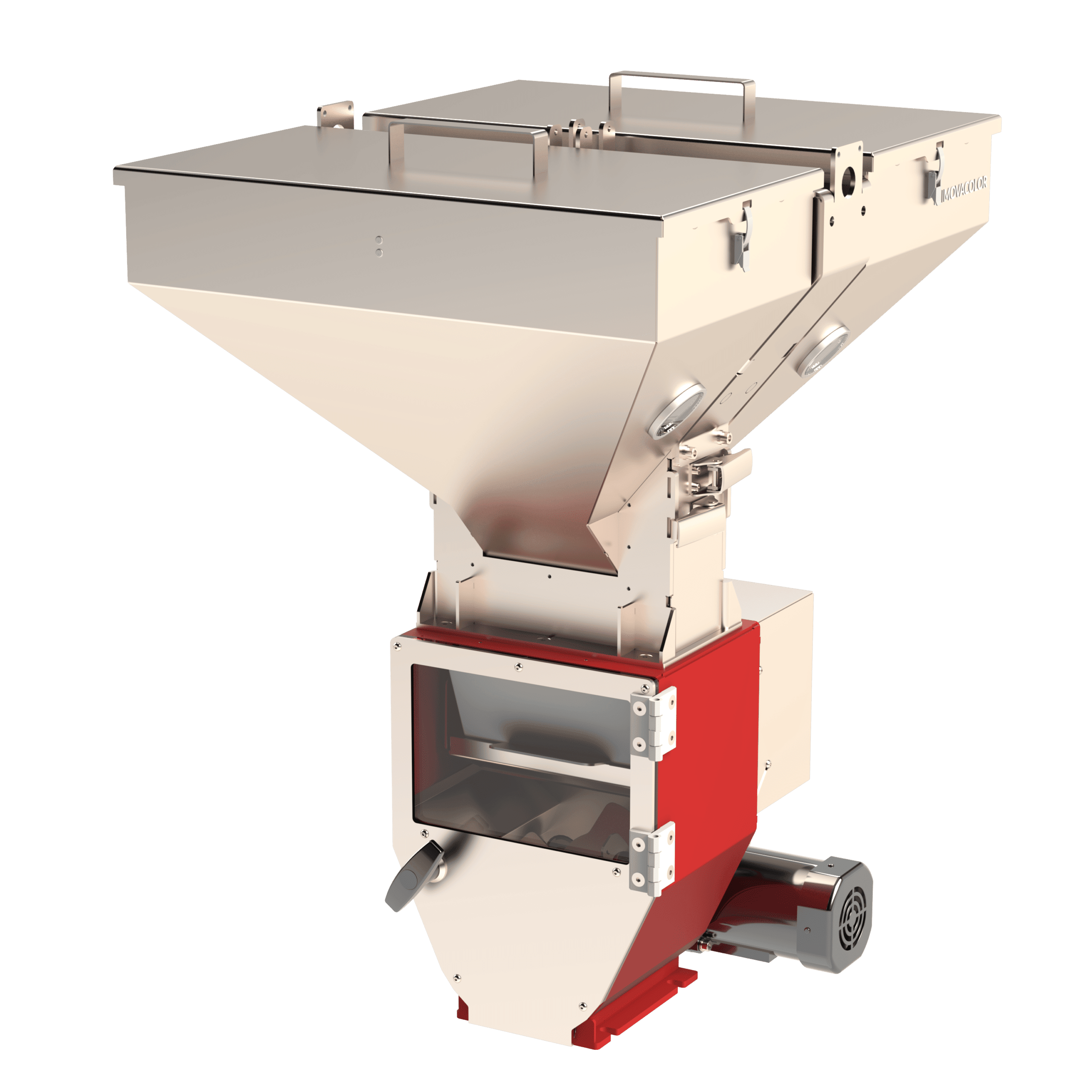

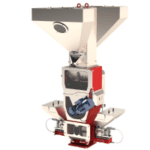

The MBS Blender 3-series, part of the MBS blender range, provides a robust and durable solution for efficiently weighing and blending materials. Its compact design without mechanical parts or cables in the removable hopper allows them to be easily accessible for cleaning, material changes, and other routine maintenance tasks. Additionally, the blender 3-series is perfectly suitable for handling a wide range of materials up to 70 degrees with a throughput of up to 480kg/h.

Thanks to its unique valve design and gain-in-weight technology, it effectively dispenses several additives into a weighing chamber and accurately measures the additives added to your production process. After your material is weighed, it’s dropped into the mixing chamber, and fed to your production machine.

The MBS Blender offers all manufacturers extensive control over their production process and consistently proves its value in all applications by helping manufacturers significantly improve efficiency, reduce waste, and save costs, resulting in savings on materials and improved quality.

Standard Equipment

- Weighing bin with 1.4kg batch size

- 3-liter mixing chamber

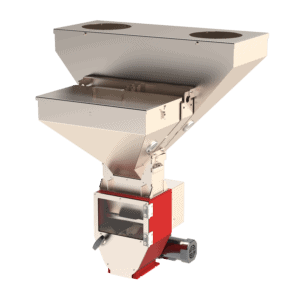

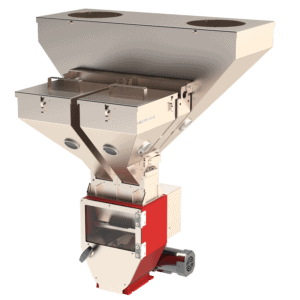

- Easy hopper removal system

- Easy weighing bin and mixing chamber removal system

- Mixing chamber level-sensor air-purge

- Compressed air-gun system

- 8“ full color portable touchscreen controller

- Unique mixerblade

- Hopper loader lifting device

The MBS Blender is part of our modular dosing concept and can be tailored to suit your plastic production process.

Ready to take your blending to the next level? Contact our product specialists today and discover how the MBS Blender can help you save on expensive material by producing more accurately.