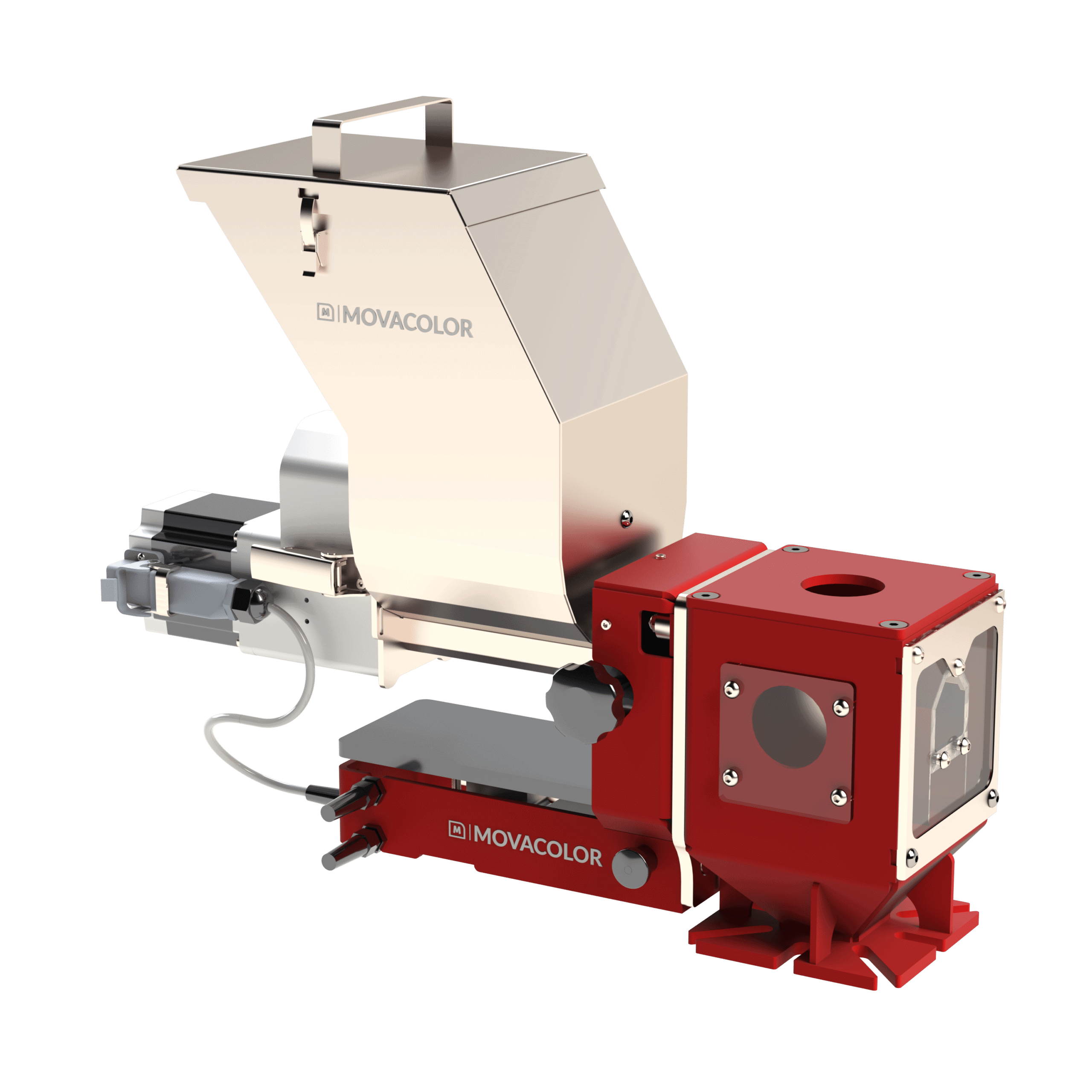

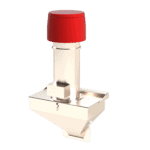

The MDS Balance Powder, part of our modular dosing solutions, is an innovative powder dosing unit that is specifically designed to tackle your powder dosing challenges, ensuring hassle-free and precise powder dosing, with up to 0.05% accuracy.

The MDS Balance Powder is equipped with loss-in-weight features, which includes a single integrated load cell with Balance technology software. Additionally, it’s configurable with a custom-engineered dosing tube, a pneumatic vibrator and agitator to avoid material clogging and rat holing, the MDS Balance Powder ensures your required dispensing accuracy for powder applications.

Standard Equipment

- 5-liter stainless-steel hopper to ensure durability, reliability, and excellent flow of powder materials, even in demanding environments.

- Hand slide hopper drain system

- Double spiral dosing tube

- Easy removable high torque motor

- Single-point 50kg load cell

- A user-friendly 8” full color touch controller for easy operation and monitoring.

- An agitator for use in powder hopper.

- Load frame

- Calibration weight

- NST40 neckpiece with single insert

The MDS Balance Powder is a versatile dosing solution suitable for various industries and applications, including injection molding, extrusion and blow molding. The MDS Balance Powder seamlessly eliminates powder dosing challenges and helps manufacturers get reliable, accurate results in their production.

Ready to take your dosing precision and efficiency to the next level? Contact our product specialists today and discover how the MDS Balance Powder by Movacolor can optimize and enhance your production process.