Micro injection molding is a specialized manufacturing process that produces small, intricate plastic parts with high precision and accuracy. This technique is an extension of traditional injection molding, commonly used for the mass production of plastic components.

Regardless of being an extension of injection molding, micro injection molding is a unique manufacturing process focusing on producing small and intricate plastic parts. Due to the size of the parts, high precision and accuracy are required to limit waste and come to a suitable product.

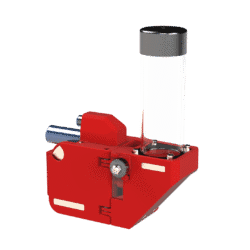

In micro injection molding, manufacturers can produce tiny and detailed features to be incorporated into the design of the plastic parts. The process involves melting a small amount of thermoplastic material and injecting it into a tiny mold cavity, where it solidifies to form the desired product. The molds used in micro injection molding are specifically designed for miniature parts, and the process is well-suited for producing components with dimensions in the micrometer to millimeter range.

This technology is particularly valuable in industries where miniaturization and precision are crucial, such as electronics, medical devices, automotive, and telecommunications. Micro injection molding allows for producing small and intricate parts that may be challenging or impossible to manufacture through other methods. The process offers advantages like high repeatability, tight tolerances, and cost-effectiveness in producing large quantities of small, complex components.

For some applications, dosing additives into the production of small plastic parts plays a significant role in the quality of the final product. For example, in the automotive industry, certain additives will likely serve the final users with added durability or, in some cases, even safety. This is particularly true within medical applications, where color might act as a distinction for doctors to use the right plastic part for their application. If we take another example, microinjection for medical applications requires the highest possible accuracy to ensure that products can not interfere with a health professional’s job or, worse, interfere with the quality of the healtcare provided due to a lower quality of a medical product.